MS XTEC is your certified supplier and high-reliability manufacturing partner for safety-critical government projects in defense, aerospace, and security technology. We manufacture ruggedized precision components and assemblies for critical applications using advanced 5-axis CNC machining, meeting the highest standards in regulated industries. Our manufacturing solutions deliver ultra-durable, application-specific parts for protective systems and mission-critical applications – from prototypes to full-scale production. Whether aerospace, aircraft, ground defense, maritime technologies, or space and satellite systems – you can rely on our expertise in producing military-grade industrial components.

Your key advantages:

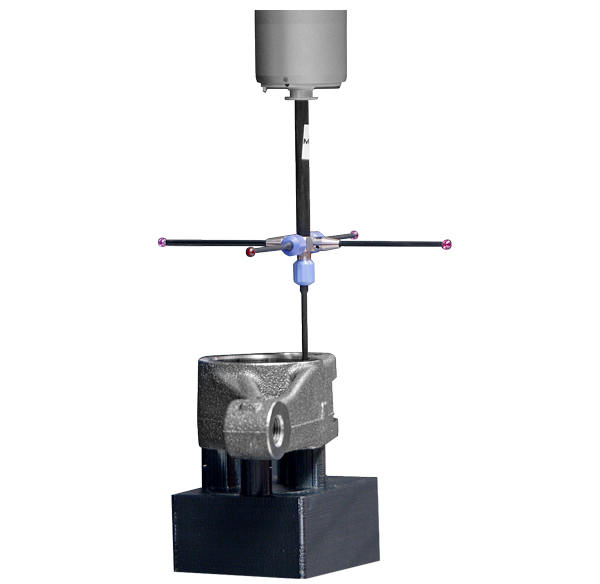

- Digitalized, cerfified processes with 100% traceability and measurement technology for safety-critical systems

- Automated 5-axis manufacturing

- Process design across the entire production chain (from raw material to finished component)

- System assembly in accordance with regulatory requirements

- Expertise in transfer projects within the defense industry

- Your reliable supplier for industrial protective technologies – with just-in-time delivery!

Ready for the toughest missions

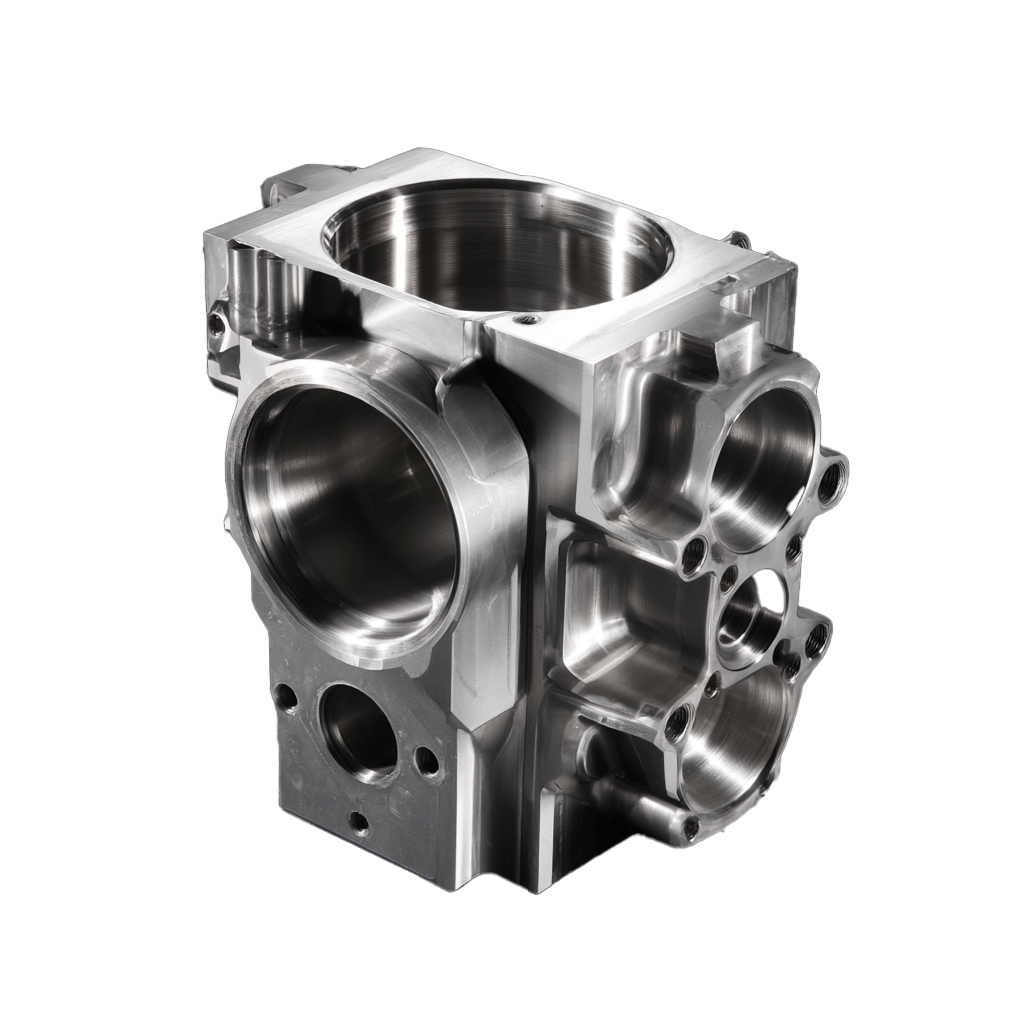

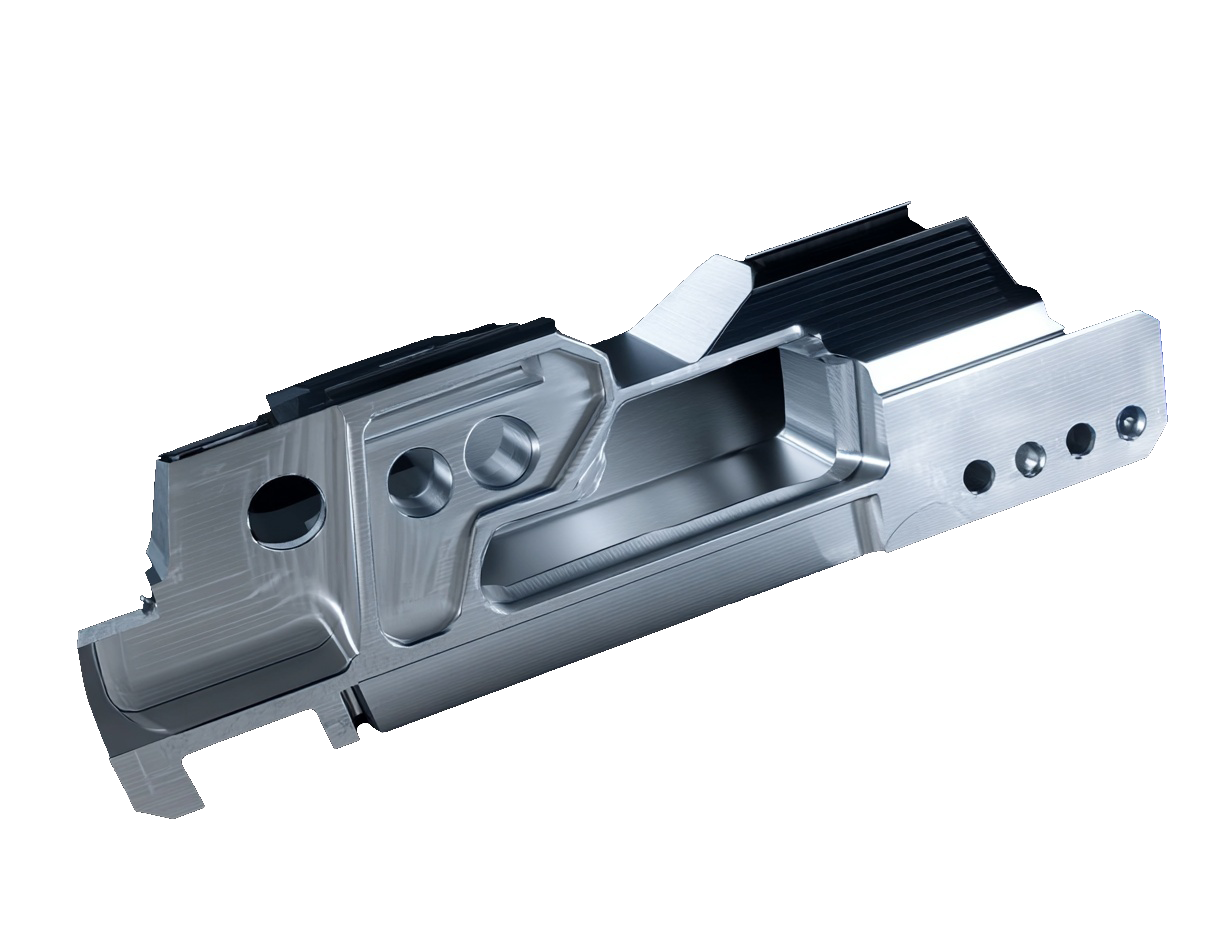

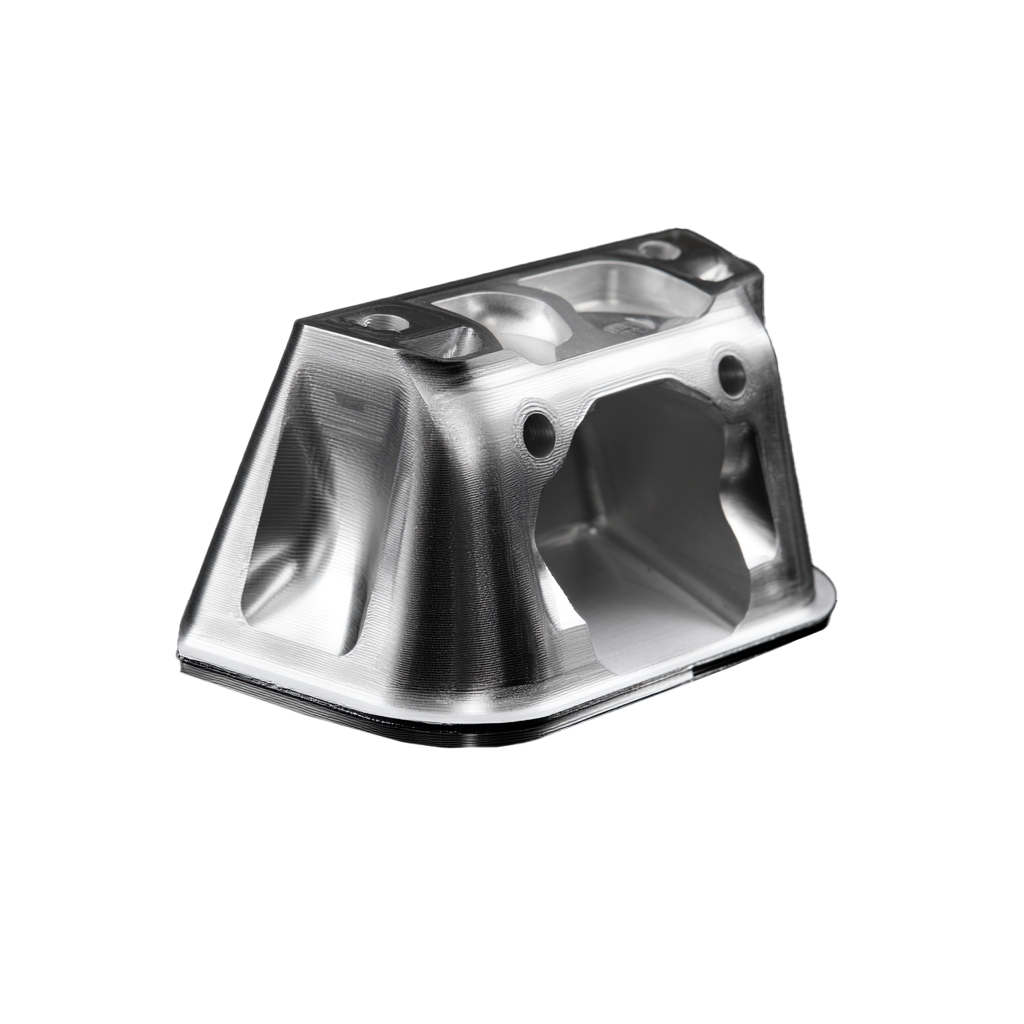

We manufacture durable

precision components.

- Range of technologies – including: machining, finishing, heat treatment, assembly, metrology, logistics, value engineering and surface finishing – supporting the production of highly robust components.

- Range of materials: Processing aluminum and steel components in multiple forms—solid, cast, or forged.

- Range of components: Highly complex CNC precision parts (turning and milling) for robust security-technology equipment as well as dual-use applications.